OUR BUSINESS

Business services

R & D support

Support R & D by utilizing many achievements and technologies

We have been manufacturing various industrial parts to support R & D.

Leveraging our many achievements and experiences, we will use the various technologies we have cultivated to provide R & D support from customer prototyping to actual machine verification processes and quality assurance tests.

METAL CASTING

Aluminum / cast iron / cast steel / various metal casting

We have been involved in casting production for various customers and have gained a lot of trust.

We produce high quality sand castings by fusing 3D CAD and artisan techniques.

We produce high quality sand castings by fusing 3D CAD and artisan techniques.

01

- Wood mold method

- Design a wooden mold based on 3D data and manufacture the wooden mold by machining.

As a feature, it can respond to mass production and flexible shape changes.

02

- AM method

- AMBy adopting the AM method(Additive manufacturing), sand molds can be made directly from 3D data without using wooden molds.

As a feature, it is possible to respond with high quality and short delivery time without a wooden mold.

03

- Casting (Aluminum / cast iron / cast steel / various metal casting)

- Pouring water (melted aluminum, etc.) is poured into the mold.

We respond to the needs of high-quality prototypes using the techniques of "advanced technology" and "takumi".

04

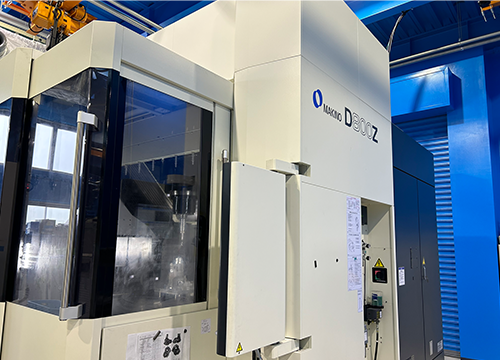

- machining

- Proto has introduced the latest equipment such as a vertical and horizontal machining center as well as a 5-axis control machining center in order to respond to all requests.

We select the most suitable processing machine according to drawing tolerances and processing direction to meet various demands.

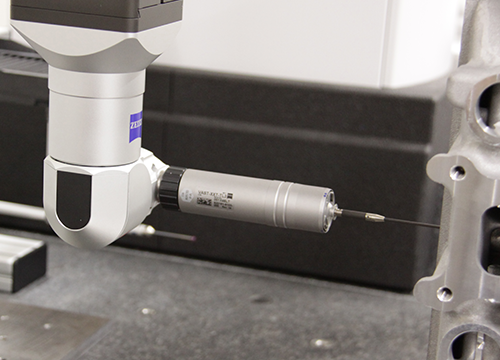

05

- 3D measurement

- We measure with the world's highest level CMM.

It measures every machined surface in micron units to determine if the product is completed according to the drawing tolerances. - For a curved surface shape that cannot be measured by 3D measurement, a non-contact 3D digitizer is used to compare and match with 3D data to confirm that there is no difference in shape.

Corresponding

We support a wide range of technologies and support all prototypes and productions.

| design | Various metal mold design, data creation from 2D drawings |

|---|---|

| Various metal sand casting |

|

| Surface treatment technology | Various heat treatments |

| Metal processing in general | Cutting |

| Inspection and measurement | Supports contact and non-contact measurement * Comparison and verification of CAD data with actual product |

Equipment list

Equipment list

| Classification | Equipment name |

|---|---|

| Casting equipment |

|

| Processing facilities |

|

| Inspection equipment |

|

| CAD/ CAM/ CAE |

|

We respond to the needs of our customers

Utilizing our many achievements and experiences, we respond to the needs of product development and prototyping departments.

- I want to make a prototype for new product development

- Anyway, I want to make it immediately

- I want to build together

- Short delivery time, declined by other companies

- Rejected by other companies due to difficult shape

- The accuracy of the contractor who has been requesting has been reduced

- Looking for a new outsourcing company

Proto casting is ideal for a wide variety of industries

- Car manufacturer

- Motorcycle manufacturer

- Various research institutions

- University research institutions

- Electric manufacturers(Motor, air conditioning)

- Cooling and air conditioning manufacturer

- Ship and aircraft manufacturers

- Industrial equipment manufacturing

- Various parts manufacturers

- Industrial sewing machine

- Sports maker

- Medical equipment manufacturers

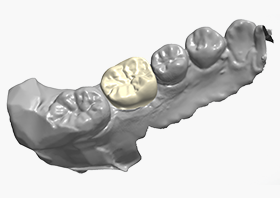

DENTAL & MEDICAL

Dental medical manufacturing

Applying cultivated technology to medical practice

Build the optimal manufacturing method

We support the provision of highly reliable prosthetic devices to provide safer treatment and provide patients with peace of mind.

We process prosthetic devices using high quality materials based on safety.

insurance coverage

CAD/CAMcrown

(Manufactured by YAMAKIN)

Not covered by insurance

e.max(Manufactured by IPS e.max CAD)

zirconia(made by Adamant)